What is Acrylic Materials – Properties and Uses

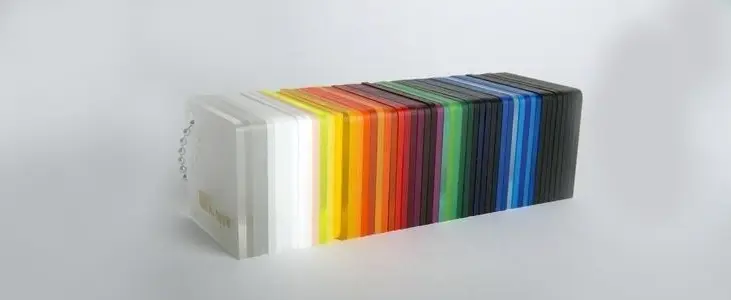

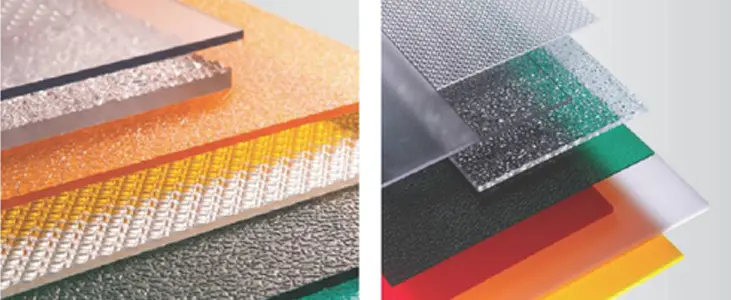

The DIYers and DIY home improvement projects we champion are a big part of who we are. In addition to easy, cheap DIY projects, acrylic plastic helps customers to achieve long-lasting, long-lasting results. Our most popular plastic material is acrylic, also known as Perspex, Plexiglass, and PMMA. With a range of colors and finishes to choose from, as well as several thicknesses and finishes, it is a cost-effective, easy-to-work-with material.

The affordability and characteristics of acrylic material make it an ideal replacement for glass in a range of home improvements. A review of the benefits of acrylic plastic will be provided in this blog, as well as suggestions on how to use it in your home. The goal of this blog is to teach you everything you need to know about acrylic.

What Is Acrylic Material

It’s very likely that you are wondering what acrylic material is, and what does it do? Thermoplastic homo-polymers, such as acrylic, are homo-polymers that have some transparency. Acrylic is a type of plastic, but what exactly is it? Known also as plexiglass, this substance is a type of trading plastic. Does acrylic material have a plastic composition? There’s a similarity between this stuff and polycarbonates.

Having the ability to withstand impact, is similar to this. It is possible to use plexiglass when you do not require the extreme strength of polycarbonate. 1928 was the year when plexiglass was invented. Hydrocarbon fuels are distilled to create it. A group or fraction of these is made light. Plastic is then formed by mixing them with a catalyst.

Acrylic: What Is It Used For?

As a result of World War II, tanks and other machines were covered by combat teams. However, the glass shatters and they were not interested in it. As a consequence, acrylic material became excessively used.

There are some types of acrylics that are transparent and can resist impacts. These two properties enable them to be used for the production of lenses, acrylic lights, acrylic nails, security walls, acrylic medical tools, LCD screens, and acrylic furniture alternatives. The fact that they are clear and allow light to pass through makes them useful for other purposes as well. Additionally, they are used to create windows, tanks, and enclosures for exhibits.

There is a possibility that you will find them in several tones and even in a transparent state. Despite this, raw materials are completely transparent. This makes it a good substitute for glass. The reason it is better than polycarbonate is that it is less costly and easier to find on the market. Manufacturers cover polycarbonate coatings with acrylic materials to make them scratch-resistant. As a result of this method, a bulletproof glass-like product is created. The acrylic material protects against daily wear and tear while polycarbonate prevents bullet entry.

Acrylic: Types And Properties

In order to know which acrylic materials you can use, you need to know how they are made.

This trading term – plexiglass – was created by a chemist in Germany named Otto Rohm. The material is also referred to as Lucite. The main characteristics of this material will be discussed next. These days, acrylic sheets come in different colors and thicknesses, making them more common.

- Plastics such as acrylic fall comes under the thermoplastic category. In contrast to thermosets, they are thermoplastics. As a result of acrylics’ reaction with heat, the term is used.

- The melting point of acrylic might be of interest to you. The material melts at a temperature of 126 °C and becomes a liquid. It is the best advantage of acrylics to be able to reheat them even after they have cooled down.

- Plastic has not been severely damaged. It is not possible to burn these materials. Injection molds and recycling both require these, so you can use them both.

- The thermoset materials can only be heated once in perfect opposition. As soon as the thermoset is cooled, you will see it burning if you try to heat it. Therefore, thermoset materials cannot be recycled.

Here are some of its scientific properties

- Acrylic is scientifically known as PMMA.

- The chemical formula of this substance is C5H8O2.

- There is a melting point of acrylic of 126 degrees Fahrenheit or 130 degrees Celsius.

- It’s typical for acrylic injection to have a value between 79 and 107.

- The temperatures here are 95 degrees Celsius or 233 degrees Fahrenheit, and are deflected at those values. Approximately 46 MPa of pressure is encountered at zero points.

- 64 MPa is the tensile strength.

- Those are 90 MPa flexural powers.

- 1.18 is the specific gravity.

- Having a shrinking rating between 0.2% to 1%, it has a rating of two points.

Is Acrylic Toxic?

Acrylic doesn’t degrade when exposed to water because it is free of bisphenol A (BPA). Acrylic does not contain BPA, unlike its related plastic, Polycarbonate, which contains BPA. Most studies with government funding showed BPA to be a hazardous risk to health while many with industry funding showed lower to no medical risks. A number of studies have linked polycarbonate to BPA release despite contradictory findings.

This has led to the advent of “BPA-Free” polycarbonate products (commonly shown on consumer products such as canning jars). Unlike PC, acrylic is a solid substance that is not contaminated with BPA. That said, fumes from 3D printing with acrylic or from the molten material used during injection molding should not be inhaled and these manufacturing processes should be conducted in a well-ventilated facility to avoid the potentially hazardous effects of gaseous polymer.

Conclusion

The strength and impact resistance of acrylic is relatively low. When it comes to highly demanding applications, polycarbonate is the better choice. It isn’t very strong and cracks instantly without much bending due to its brittle failure. You now have a better understanding of acrylic melting temperatures. You are also familiar with the applications of acrylic. We hope you have discovered a multitude of other properties after learning about acrylic.

Plastic products are designed, engineered, tooling, and manufactured by Pleasant Plastic. With our experience in acrylic engraving / engraving services in Dubai, acrylic painting and designing in Dubai, and acrylic laser cutting in Dubai, we are the best acrylic product designers in Dubai, UAE. Not only are we proud of the efficiency of our work, but we are also proud to deliver orders on time. For Acrylic Bending and Molding in Dubai, Pleasant Plastic is famous and is evident from the picture. For more information, please contact us.