Acrylic Laser Cutting: The Complete Guide

If you know the effort behind dragging a saw through the edges of an acrylic sheet. As an acrylic company in Dubai, you will know the amount of effort that it requires as manual labor. Using traditional tools may be time-consuming and worse, you may not get your desired results. Laser work has gained a lot of attention in recent years. It has paved its way to the workstations of many professionals.

However, working with a laser is not the easiest task. Considering you are acrylic fabricators in Dubai, if you are new to lasers, you need to gain knowledge and experience to function properly. Hence this is a guide that will help you get a start. Here, we will talk about the complete deal with lasers on acrylic sheets. Also pointing out the basics of acrylic laser cutting in Dubai and its mechanism as well as the pros and cons. Hopefully, it will help you gain some courage to go near the beam and thus flourish your business. Before we begin, we need to understand what exactly laser cutting is and why it has been gaining focus.

What is laser cutting?

The traditional way requires a lot of work of tools. Some include drills, saws, and other materials. With laser cutting on acrylic products not only that the process becomes easy with relatively less requirement of tools and other proceedings. It is also time-saving and incredibly efficient. Moreover, there are fewer chances of injuring yourself.

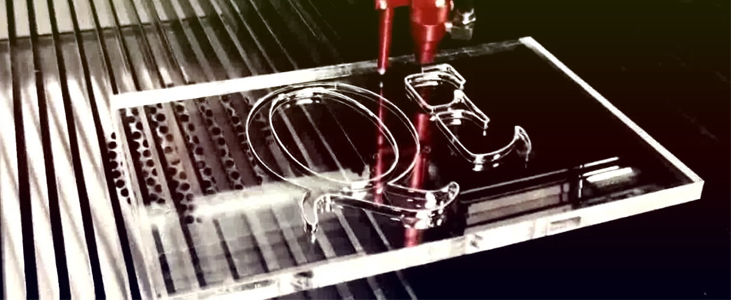

By definition, laser cutting on an acrylic display is the digital eliminating creation method. It involves the work of a laser to ensure the safe cutting of your material. The mechanism is quite simple. The laser’s heat simply accurately cuts from the object. The pressure point is the same, the laser happens to follow the guideline with manual help. It exhibits fantastic detailing over acrylic painting and designing and more.

This system heats the surface to the extent that it evaporates the material to accuracy. This happens due to the light beams which are rather high-powered.

Some basics

If your organization is working to make accurate products with minimal wastage, laser cutting is the option you should go for. You can opt for any shape and size in various one thing about acrylic material is that it comes in two variants. That includes extruded and cast. Even though you happen to find them look alike, many people choose one for a lot of reasons. The material and the ability to cut through, rather the tensile strength varies.

Nonetheless, you should understand your requirements and then select your preferred acrylic box. Before you start playing with the laser you need to calm down and understand that it requires a lot of attention. That is because it is extremely powerful and the heat waves cut through anything. Hence it is important to keep in mind some safety measures that will help you through the process. To give you a better idea, here are some basics that will give you a better understanding:

Safety measures

The most common thing to keep in mind during laser work is to be careful not to burn yourself. Many people have had accidents with such lasers and significantly happened to injure themselves. This mostly happens to rookies who are new to using a laser. This is not limited to just burning yourself. You need to understand that laser work is a chemical process. And it mixes with the material core when it is cutting through. While practice makes it perfect, it is important to note down some tips. These will help you even if you are an experienced user.

What to do with the fumes?

First and foremost, wear a mask. While that stands true for corona as well, when you are working with acrylic bending, wear a mask to protect yourself from fumes. Should you be exposed to it, you may suffer from a lot of health problems in the near future. That’s not all, you will experience a lot of fumes which will prevent you from seeing. Hence be sure to also wear your glasses to protect your eyes. Also, ensure that you are wearing your protective gear to maintain the consistency of your work, thus making it flawless.

One great fact is, you can avoid all this just by polishing the surface before you start working on it. Nonetheless, it is always best to ensure protection before you start your work. The polish will make the process smooth and easy, you will be able to cut through the Acrylic Sheet Thickness without any hassle. But make sure that you do not glue the edges and the sides which you need to glue.

How to not burn yourself?

When you are playing with a Fiber Laser Cutter, you are bound to get burned. Actually, that is true for fire. Nonetheless, if you are using a laser you need to keep yourself from getting burned. We discussed earlier, that lasers are basically high heat waves that melt the acrylic lighting fixtures and give you a complete finish. That is why we have brought to you some tips to prevent yourself from getting burned. But first and foremost, remember that it is absolutely basic to wear all necessary protective gears. Now that we have established that, let’s talk about additional protection:

- Make sure that the temperature of the laser is moderate or according to your comfort.

- Try not to misuse the laser

- Careful with the material. Try not to go near the laser.

What is the extent of thickness in acrylic laser cutting?

If you are working with more than 6 inches then the best thing you can do is, lower the speed and increase the power. The laser beam slowly melts the edges and cuts through the acrylic sheet. The end result? You will get more smother polished finished edges. This is also a popular method for acrylic engraving through a perfect laser.

Types of laser cutters

Consumers have different wants and needs and they keep changing their minds. So, to be prepared for that, there are a wide variety of laser cutters available to meet their needs. Interestingly, all laser cutters are built in a similar way. The difference is the power range and their purposes.

Neodymium lasers

These lasers are formed with doped crystals of neodymium. They provide fantastic performances with a lot of intensity. Hence they are specially made to cut through thick acrylic materials.

CO2 lasers

These lasers run through carbon dioxide gas which is generally electrically stirred. A great thing about this is that the average cost is really moderate since it requires less power to function. It is also worthy of its price as it is a long-term investment.

Mistakes that happen more often

While everybody works to learn about lasers and how to function them. But whether you are a rookie or a novice, or even an expert, you will make mistakes. Thus let us know what those mistakes are and what we can do about them.

Flare-up

When you are cutting relatively thicker types of material, you may get a flare-up which can be dangerous. This usually happens depending upon the power of the machines and their thickness tolerance for material types. You can avoid this by creating a vacuum. This can be done by blocking the openings and creating a suction. Hence it causes a better passageway for gases and creates airflow. Another way to go about with acrylic sheet cutting is with nitrogen assist.

This process is perfect for cutting through a variety of materials that are thick.

Advantages and disadvantages

The great thing about laser work on acrylic tables is that the culture is accepting it more and more. It is thus the preferred way of working because it is fast, accurate, and efficient. In this verse, we will talk about the key advantages and disadvantages that come with lasers:

Pros:

Fast and efficient

The heat waves from the laser cutting machines make it super easy and efficient on the surface. The concentration of the waves is thus so high, that it can melt at one point without any hassle. It is also very fast and makes your work more productive and easy.

Flexible

So you do not have to carry a bunch of tools. That would contain a saw, polishing instruments among other things. For Laser Cutting Acrylic products, you will have to carry out just the laser. You may also set it up in your garage or the preferred location. Since it does not take much space, you can create a nice and small workshop for your benefit.

Precision

The laser cuts the surface at one point. This means all you have to do is move the acrylic roofing sheets to get it cut. Since there is just one beam concentrating on the surface, you can make your cuts more accurately. Acrylic jewelry businesses apply this process because of the guaranteed precision.

Convenience

One of the major reasons why laser acrylic plastic finishes are more preferred is because of how convenient it is. All one needs to do is set it up somewhere and enjoy the acrylic cutting process. It eliminates the hassle of tools and other amenities that are required usually if you opt for the traditional acrylic shaping technique.

Safer

While laser usage has its own set of dangers, it does not compare to the dangers and risks of traditional tools. You may severely injure yourself when you are using a saw for Acrylic Mirror Sheet Cutting. These examples are so frequent that many people have switched to laser usage.

Cons

It can be expensive – although it is a fantastic investment, the initial amount may be a bit much for 1 Acrylic Processing Machine Setup. Nonetheless, many people have found it helpful in the long run.

Experience

Earlier we discussed that there are some precautions that are needed to be taken, especially while cutting through durable materials. Initially, though, that may be a little difficult to follow. However, it is a very good investment of time and effort that you put into learning the process.

FAQ – Frequently Asked Questions

What Is Acrylic Laser Cutting?

This is a process wherein one uses a laser beam to cut through or make designs over acrylic glass sheets. It provides more accurate cuts and designs. It is thus preferred by many craftspeople.

Is there any difference between an acrylic laser cutter and an acrylic laser engraver?

There are many patterns that a customer demands. Accordingly one uses either a laser cutter and a acrylic laser engraver. The difference is that laser cutters give accurate edge cuttings. While laser engravers are rather mild wherein it is careful not to cut through the sheet. Instead, you can create Acrylic shapes and wanted designs.

Why should I go for an acrylic laser cutting machine as opposed to other conventional cutting methods?

There are many advantages of using a laser on acrylic sheet suppliers in Dubai instead of the traditional ways. Few reasons are that traditional tools are comparatively more dangerous. Additionally, Acrylic laser cutting machines provide more accurate and edgy cuttings. The process is also very fast and smooth. If you make sure that you are following all the guidelines and safety precautions, you can get terrific results.

Conclusion

Laser cuttings on acrylic sheets are getting popular by the day. Many people are progressing towards a far more creative and fast process. while lasers have their own set of disadvantages wherein, there may be some health problems. With proper precaution and care, you can manage to satisfy your customers without having to sacrifice your health.