Ultimate Guide to the Different Types of Acrylic Sheets

Acrylic or Plexiglass is a common type of plastic popular for its glossy feature, great impact resistance, and exceptional scratch resistance. The material incorporates high load-bearing capability when compared to the toughest materials like polycarbonate. Acrylic company in Dubai concentrates on the delivery of various types of acrylic sheets with different features.

To meet specific requirements of the industries and owners, the acrylic sheet providers design the acrylic in various models. If you have an idea for doing a specific project and wish to find the right base material to accomplish the design, reliable acrylic fabricators in Dubai can offer you the type of acrylic sheets that suit your requirement.

This blog post can help you out to know about the right types of acrylic sheets that serve your needs.

Contents

What are Acrylic Sheets?

Acrylite is yet another name for acrylic sheets in terms of the brand. Other names include Lucite, Perspex, and Plexiglas. This material is famous for its glossy shine. It also has great power to prevent impacts and scratches. The item has the skill to bear a higher weight when compared to polycarbonate. In short, it is the strongest material available. Each sector needs a particular kind of acrylic to complete its production. It is easy to remove the scratches and regain the texture of the base material. You can use various methods to remove the scratches from the acrylic sheet.

Different Types of Acrylic Sheets

The optical clarity, stiffness, and strength of acrylic have made it a personal preference of many to fit the requirements of businesses and personal purposes. Acrylic sheets are durable and UV-moisture resistant due to which they are used widely in exterior applications. They weigh about 50% less compared to the weight of glass, which means they are highly compact. Acrylic roofing sheets, acrylic panels, and acrylic fixtures use the sheets to maintain high-end durability due to the quality of materials used. Here are some types of acrylic sheets you can look for.

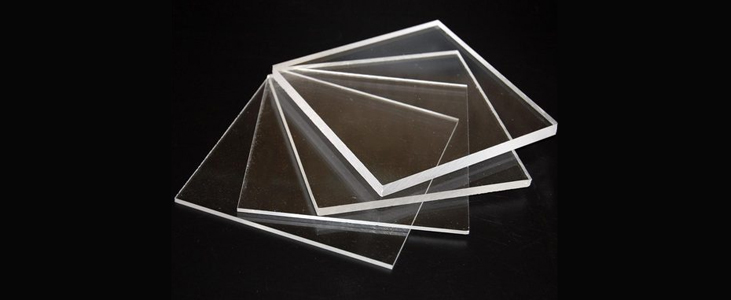

1. Clear Acrylic Sheet

A clear acrylic sheet is one of the most common types of acrylic sheets. This kind is highly remarkable in terms of the dimension types. Its thickness falls within the range from four inches to one by twenty-fifth of the inch. The width ranges from 3 ft to 10 ft and the length values range between 4 ft to 12 and a half feet. Hence almost all known design dimensions can use these varied dimensions to build the ideal product. Clear acrylic sheets find application across various areas that include acrylic roofing sheets, acrylic sinks, acrylic bathtubs, acrylic aquariums, etc.

2. Textured Acrylic sheet

These acrylic sheets are powerful and aesthetic at the same time. It is used instead of glass for several productions. The textured acrylics are used as separations in between any room, patio table, or cabinet. They are useful since the material withstands force and allows maximum light to pass.

3. Impact Altered Acrylic sheet

Do you know that acrylic is 17 times stronger than glass? Though acrylic doesn’t have high impact resistance, it is the material preferred than glass. Altered acrylic has the power to increase such impact resistance skills. Acrylic material is similar to polycarbonate. The best part here is that this acrylic transparent sheet also offers optical clarity, weather resistance, and budget-friendliness.

4. Anti-Static Acrylic Sheet

Acrylics offer extreme safety to several varieties of electrical parts. Even then many are scared of the acrylic’s electrostatic power. These discharges can be adversarial to the electrical parts. It embraces a transparent cover that surrounds it. The cover prevents any electrostatic discharge. Another advantage is that this covering is permanent. Hence no humidity can affect the electrical parts in anyways.

5. Lucite Blocks

If you want to complete a job that needs detailed lighting works, then this sheet will work wonders. The sheet creates a balanced diffusion for glowing. It embeds LED lights in the material directly to make this happen. It also helps you to consistently keep the same shade for transmission. This is possible notwithstanding the light source for outdoor as well as indoor projects.

6. Abrasion Resistant acrylic sheet

Abrasions bombarded the Acrylics in the past. Hence, a new product that has two coats on it offers matchless durability. Scuffs and scratches can no longer affect the products. The public environment needs such sturdy materials. Moreover, the material offers resistance to damaging and abrasive chemicals. They offer many times the impact strength compared to glass. Nevertheless, they have amazing optical quality.

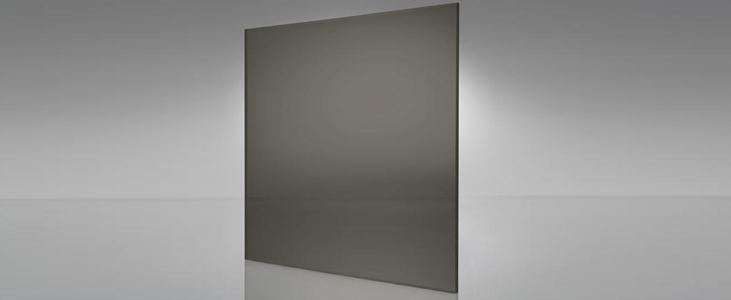

7. Solar Tints

Ultraviolet rays can harm precious stuff. This is now not an issue after the advent of the solar tint coats on acrylics. Additionally, it controls the temperatures in any building to lower the costs of the material. Thus, this sheet offers awesome safety from the sun’s harmful rays. As an added advantage here the sheet will not create bubbles or peels as it weathers. They reduce the solar energy transmittance and the solar glare to a great extent.

8. Mirror Acrylics

These sheets offer a great reflecting surface in places that suffer the highest stress and are service-related. Moreover, you can choose from 14 types of shades. The acrylic transparent sheet comes with a blend of form and function to offer high-end durability. It acts as a resistant reflective surface to enable great service in even stressful environments. Available in various colors, they look beautiful and bright.

9. White acrylic sheet

Some applications might demand irregular dimensions. You might require opaque products to fulfill such applications. In this circumstance, you can make use of white acrylic sheets. Though they look black and dull at the first sight, they turn white under the LED lights. These products can be used to create outdoor signs and ads. Since they are sensitive to light, they can be visible only with LED light.

10. Colored Acrylic Sheet

If you look for a colorful and vibrant option in the acrylic sheets, you can go for colored acrylic sheeting. They consist of more than twenty different hues and primary colors for your choice. These varieties are strong, beautiful, and can offer top-grade durability. If you look for an acrylic sheet that stands out in terms of color menu, have a look at the fluorescent acrylic sheets in the transparent colored sheets that glow in the light.

11. Light Diffusing Acrylic Sheet

The light diffusion feature of this acrylic sheet prevents luminance fluctuations and distinct hotspots. This acrylic sheet is an ideal option to use in the backlit letters and signs. If you compare the difference between the light-diffusing acrylic and the basic acrylic, you can see that they make customizable channel letters to help signage company with affordability and few lighting sources.

12. Non-Glare Acrylic Sheet

When you don’t need to keep the light out completely, and you look to minimize the glare in the display cases of your valuables, you can use the non-glare acrylic sheets. This matte finish acrylic sheeting offers assured protection for your products and lets you have unobscured attention on whatever you sell or display.

13. UV- Filtering Acrylic Sheet

If you search for an acrylic sheeting specially designed to protect from the rays of the sun, then a UV filtering acrylic sheet is helpful. These sheets can help to curb the transmission of toxic UV rays. This acrylic sheet can be helpful to meet the unique needs of artists, museums, and photo framers to safeguard the artwork and important documents against degradation or fading from UV rays.

14. UV Transmitting Acrylic Sheet

In contrast to the UV filtering acrylic sheets, UV transmitting acrylic sheets let the UV light pass through. These are significant in medical treatment and tanning beds. They let in more than 92% of the Ultraviolet rays and provide benefits similar to that of traditional plexiglass. These include high impact resistance, ease of fabrication, and effortless fitting.

15. Frame Grade Acrylic Sheet

This acrylic sheet has framing applications and forms a classic standard in framing photography and art. These acrylic sheets are safe since they involve in-depth camera inspection to make sure there are the least imperfections. The frame-grade acrylic sheets contribute to high clarity, superior color, and material integrity. This acrylic sheet can absorb up to 98% UV rays and weighs only half the weight of conventional glass.

Main Properties of Acrylic Sheets

You must be knowing that the acrylic sheet has these main properties. It is a transparent plastic substance. Nevertheless, the substance is strong, stiff, and has optical clarity. You can fabricate the sheet easily. It also bonds properly with most adhesives or solvents.

You can thermoform this cool material, too. When you compare it with other plastics, these sheets possess superior weathering properties. Since acrylic is a durable material, it has become the personal favorite of many industries and individuals.

Acrylic paint is also common among artists and beginners to paint amazingly on the canvas. Get a step by step guide to start acrylic painting and consider the points to gain expertise with practice. Also, don’t forget to check out our blog to gather more acrylic painting ideas to make your painting fun.

Best Applications of Acrylic Sheets

Mostly the sheets are favorite materials used in the construction industry. Moreover, now buildings defy the logic of physics. Thus, they now require a tough material. Hence acrylic sheets are used for glazing effects in commercial and structural areas. You can create the display and point of sale.

Acrylic sheet is also used in merchandising. It is a significant sign material to develop internally lit letters and faces, especially to contribute to outdoor use, where sunlight resistance and weather-resistance is crucial.

The core applications of acrylic sheets are Lenses, acrylic nails, security barriers, LCD screens, medical equipment, and furniture. They are also used in the safety shields, window glazing, acrylic wedding invitations, exhibit enclosures, inspection doors and windows, machine covers, etc.

This is not the end of what acrylic sheets can do. Acrylics are the integral elements used in acrylic fixtures, acrylic display cases, counter dividers, household equipment, cases of vending machines, and the various other industrial machines.

Acrylics can also resist corrosion and breakage. They can diffuse and transmit light seamlessly, which has blessed many industries. Acrylic is used in acrylic lighting fixtures, design space, and the popular dome skylights, which serve the commercial, industrial, private, and public buildings with daylight admittance features.

Get more details about the core acrylic products in the market.

How to Cut an Acrylic Sheet?

Here is the step-by-step guide to cutting the acrylic sheet :

- Place the material onto any flat surface

- First, begin measuring a line using a yardstick

- Draw a line with the yardstick and a pointed marker

- The line will guide you to cut the material properly

- Now start scoring on the sheet using a utility blade while pressing the yardstick on the drawn line

- Repeat the scoring ten and twelve times

- Check if there is a correct groove on the material

- Change the side of the material and begin scoring that side in the same manner

- Start clamping the sheet with the drawn line facing the work areas edge

- Then use a strong downward pushing movement for snapping the area in the sheet which exceeds the work area.

- The material will snap away according to the desired measurements.

How to Choose a Reliable Acrylic Supplier?

Acrylic sheets are of various kinds and the above list might have made you clear about most of them and their differences. You can now easily pick up your preferred acrylic type to finalize your tasks. Various acrylic sheets offer different benefits and serve a multitude of purposes for industries and businesses.

Only a reliable acrylic supplier can understand the type of acrylic sheet you require and contribute to the needs with utmost satisfaction. Pleasant Acrylic takes care of end-to-end product design, engineering, and tooling of acrylic, being the leading acrylic manufacturer. This acrylic company in Dubai, UAE offers you the benefits of availing of Acrylic sheet Dubai. Acrylic bending and molding along with the quality assured for the acrylic plastic supplied.

Frequently Asked Questions (FAQ)

-

Is acrylic sheet cheaper than glass?

When compared to glass, acrylic is a more durable and cost-effective option. They are compact and relatively portable. Since acrylic takes less time to make and offers a lustrous shine, acrylic plastic is an ideal option over the glass.

-

Is acrylic expensive?

Regardless of fabricating the material in the cast or the extruded process, acrylic is inexpensive while also when compared to glass, it offers 10 times more impact resistance. The product has high-end durability, and you can use it for a broader temperature range.

It also has improved weather resistance, contradicting glass, and different forms of plastic. The acrylic sheet price in UAE. The acrylic sheet price in Dubai is inexpensive when you have a reliable acrylic supplier to offer the type of acrylic sheet you require.

-

How to measure acrylic sheets?

Acrylic is robust, however, it needs support when you use large acrylic sheets. Hence, if the dimensions are higher, choose a thicker sheet. For example, when the sheet is about 1 sq.m, then 2 mm will be apt, and for anything between 1.5 to 2 sq.m, the minimum thickness would be 4 mm could be the thickness required.