How Does Laser Engraving Work and Why Is It Popular?

Laser engraving has become one of the most precise and versatile methods for customizing and personalizing products, especially in the acrylic industry. Its ability to produce detailed and permanent designs with high accuracy has made it a preferred choice for both businesses and individuals. In this blog, we’ll explore how laser engraving Dubai works, why it’s popular, and why it’s particularly beneficial for acrylic products.

What Is Laser Engraving?

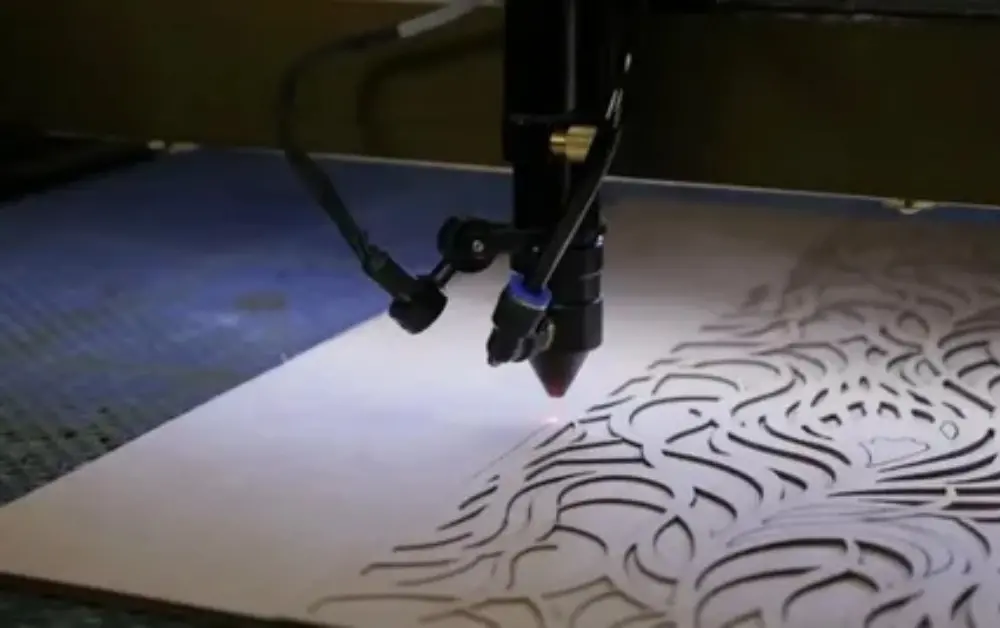

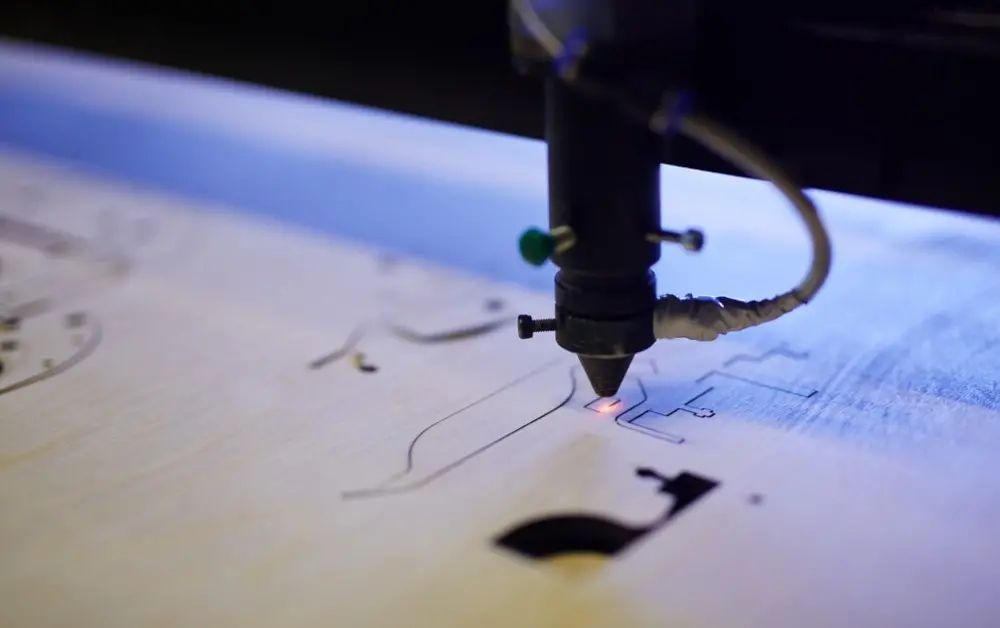

Laser engraving is a process that uses a high-powered laser beam to etch or cut designs into a material’s surface. Unlike traditional engraving methods that use physical tools, laser engraving relies on focused light to create precise and detailed marks. This process involves the following steps:

- Design Creation – The design is created using specialized software and then uploaded to the laser engraving machine.

- Material Placement – The acrylic product is placed securely on the machine’s platform.

- Laser Activation – The machine generates a concentrated laser beam that heats the acrylic surface, causing it to vaporize and create the desired pattern or text.

- Cooling and Cleaning – After engraving, the product is cleaned and polished to remove any residue and enhance the finish.

The precision of the laser allows for complex patterns, detailed artwork, and text to be engraved with high accuracy, making it suitable for a wide range of applications.

Why Is Laser Engraving Popular for Acrylic Products?

1.High Precision and Detail

Laser engraving can create intricate designs and fine details that are difficult to achieve with traditional methods. The focused laser beam ensures consistent engraving, even on small or complex patterns. This is particularly valuable for acrylic products, which require clean and polished finishes.

2.Permanent and Durable Results

Unlike printing or surface marking, laser engraving creates permanent marks that do not fade or wear over time. This makes it ideal for acrylic signage, decorative items, and branding materials. The engraved design remains intact even when exposed to moisture, UV rays, and regular handling.

3.Versatility in Design

Laser engraving allows for a wide range of design options, including logos, text, patterns, and images. Acrylic can be engraved with various depths and textures, creating both subtle and bold finishes depending on the desired outcome.

4.Fast and Efficient Production

Laser engraving machines can complete complex designs in a short time without compromising quality. This makes it a cost-effective solution for bulk orders of acrylic products such as display stands, awards, nameplates, and promotional items.

5.Non-Contact Process

Because laser engraving is a non-contact process, it eliminates the risk of damaging the acrylic surface. The laser beam only interacts with the material’s surface, ensuring a clean and precise finish without the risk of cracks or scratches.

Why Businesses Prefer Laser Engraving for Acrylic

Businesses in Dubai are increasingly turning to laser engraving for acrylic products because of its ability to combine customization with high-quality results. The ability to create consistent branding, unique designs, and durable products makes it a preferred solution for promotional and functional items.

In Conclusion

Laser engraving has transformed the customization of acrylic products, offering precision, durability, and creative freedom. If you are looking for top-quality laser engraving Dubai for your acrylic products, Pleasant Plastic offers expert services to meet your design and production needs.