Different Types of Laser Engraving Machines Explained

In recent years, laser engraving has become one of the most efficient and precise methods for marking, etching, and personalizing materials. From industrial applications to creative projects, this technology is widely used across multiple industries including manufacturing, jewelry, signage, medical equipment, and even art. The power of laser engraving lies not only in its precision but also in the variety of machines available to handle different tasks. Each type of machine is designed to work with specific materials and deliver unique results.

In this blog, we’ll break down the different types of laser engraving machines, their features, applications, and advantages, helping you understand which one might be best suited for your needs.

1. CO₂ Laser Engraving Machines

Features

CO₂ laser machines are the most widely used type of laser engraving equipment. They operate using a gas laser, primarily carbon dioxide, that is electrically stimulated to produce a laser beam. These machines are especially popular for non-metallic materials.

Applications

- Wood engraving

- Acrylic and plastic cutting

- Glass etching

- Leather engraving

- Paper and fabric marking

Advantages

- Extremely versatile with non-metal materials

- Provides smooth and detailed results

- Relatively affordable compared to other types of machines

CO₂ machines are ideal for small businesses, crafters, and industries that require decorative or detailed laser engraving work.

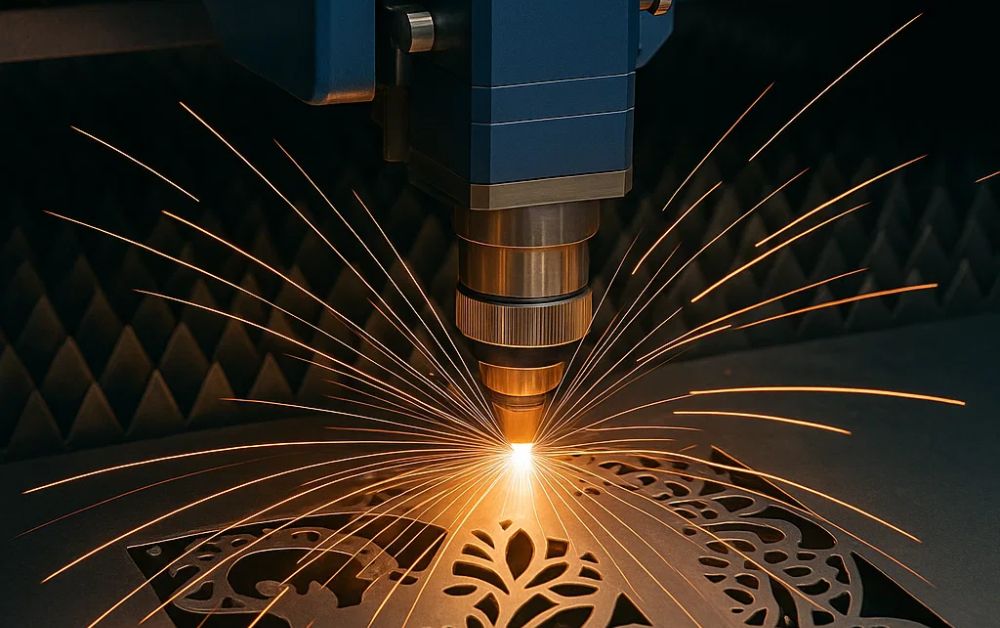

2. Fiber Laser Engraving Machines

Features

Fiber laser machines use a solid-state laser, generated through optical fibers doped with rare-earth elements like ytterbium. They are extremely powerful and efficient when working with metals.

Applications

- Engraving serial numbers, barcodes, and QR codes on metal

- Branding tools, industrial equipment, and automotive parts

- Marking medical devices for traceability

- Jewelry engraving

Advantages

- Works exceptionally well with metals (stainless steel, aluminum, gold, silver)

- High-speed marking and deep engraving capabilities

- Low maintenance and long lifespan

Fiber laser machines are the go-to choice for industries that require permanent and durable marks on metal surfaces.

3. Diode Laser Engraving Machines

Features

Diode laser machines are compact and generally more affordable than CO₂ or fiber options. They operate using semiconductor diodes as the light source. While not as powerful, they are useful for hobbyists and small-scale engraving projects.

Applications

- Soft materials like wood, plastic, and leather

- Small-scale customizations such as phone cases, gifts, and promotional items

- Lightweight cutting and surface marking

Advantages

- Portable and budget-friendly

- Easy to operate for beginners

- Suitable for simple engraving tasks

While diode machines may not handle heavy-duty industrial tasks, they are perfect for DIY projects and small businesses looking to personalize products with laser engraving.

4. Green Laser Engraving Machines

Features

Green laser machines, also known as frequency-doubled laser engravers, produce a laser beam with a shorter wavelength (532 nm). This allows them to engrave materials that are difficult for other types of lasers.

Applications

- Plastics with high reflectivity

- Certain metals and polymers

- Electronics and circuit boards

- Medical instruments

Advantages

- High precision with delicate materials

- Reduces risk of material damage due to lower heat impact

- Ideal for industries requiring fine detailing

Green laser machines are often used in highly specialized fields where precision and clarity are non-negotiable.

5. UV Laser Engraving Machines

Features

UV laser machines operate at an even shorter wavelength (355 nm), making them capable of marking sensitive materials without generating excessive heat. This process is often referred to as “cold marking.”

Applications

- Glass and crystal engraving

- Ceramics and plastics

- Silicone and rubber marking

- Microelectronics and medical devices

Advantages

- Perfect for materials prone to damage from high heat

- Provides crisp, detailed, and high-contrast engravings

- Useful for marking fine text, codes, and logos

UV laser engraving machines are widely used in the electronics and medical industries, where precision and material safety are crucial.

Factors to Consider When Choosing a Laser Engraving Machine

Selecting the right machine depends on several factors:

- Material Type – Decide whether you primarily work with metals, plastics, wood, or a combination.

- Engraving Depth – Fiber lasers are better for deep engravings, while CO₂ lasers are excellent for surface etching.

- Production Volume – High-speed fiber machines are great for industrial output, while diode machines are suitable for small projects.

- Budget – Costs vary widely; diode lasers are the most affordable, while UV and green lasers are often premium-priced.

- Customization Needs – Consider whether your business requires detailed logos, barcodes, or decorative designs.

Conclusion

Laser engraving has transformed how businesses and individuals personalize, brand, and manufacture products. With options ranging from affordable diode lasers for hobbyists to advanced fiber and UV lasers for specialized industries, there’s a solution for every need. Choosing the right machine ensures precision, efficiency, and long-term value. Among companies that excel in offering innovative and reliable engraving solutions, Pleasant Plastic shines with its commitment to quality, customization, and customer satisfaction—making it a trusted partner for businesses and creators alike.