Pleasant Acrylic provides end-to-end product design, engineering, tooling, and acrylic manufacturers. We are the best acrylic product designer in Dubai, UAE. We take pride not only in the efficiency of our job but in delivering orders from our customers on time. You can see that Pleasant Acrylic is famous for Acrylic Bending and Molding Dubai. Contact us for more.

What is Acrylic Laser Engraving – Complete Guide

What is Acrylic Engraving

The engraving on acrylic processes allows you to include distinct as well as extraordinary aspects inside the acrylic substance. It gives this result because an artist is able to literally include any design, like any light, complex or even intricately done patterns.

Many will have doubts about such an acrylic engraving machine process. That’s why we have prepared this article that will offer guidance across each of the crucial steps plus methods, and even learn how to laser engrave acrylic materials.

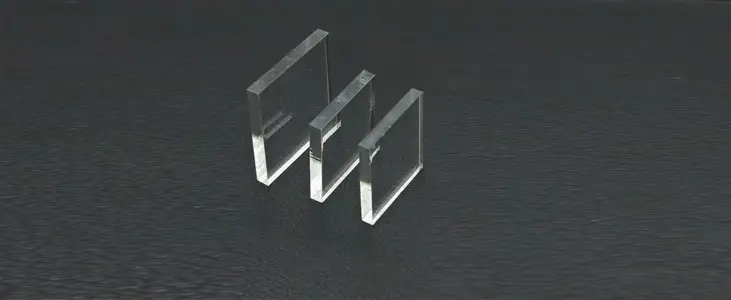

Now, you need to know the exact meaning of an Acrylic Engraving work. It is a method to print texts as well as images over the acrylic sheet. The engraving machine prints these designs. Nowadays, this method has become the best known among acrylic fabrication.

Laser Acrylic Engraving

While completing the acrylic laser engraving process over the acrylic sheet you can create a wide variety of designs. The artist will complete the step with the help of the best-quality laser engraving machine.

We will see deeper inside the machine types as well as the tips for finishing the acrylic engraving work.

Today, the laser engraver of acrylic is completing art projects for humongous companies.

The engravers have used this art form like a serious hobby.

Let us now learn the art to acrylic engrave images. You will find how to engrave acrylic using various methods.

Here, we have explained some of the current engraving methods below.

1. Mirrored Reverse Side

The method creates a base alongside utilizing cast acrylic to complete the engraving. In this method the result creates a mirror engraving behind the cast acrylic.

Usually, the end result offers a wonderful transformation.

Let us learn this method in some steps.

Prepare the Design & Place it Inside the Laser Engraver

The finished image inside the cast acrylic is kept in the laser engraver. This step begins the engraver’s work. He will power the laser machine to start engraving.

Remove the Product & Turn the Other Side

The artist engraves the similar image later in the cast acrylic. Such a step creates a clear-cut picture in the cast acrylic’s other face.

Remove the Engraved Result

Once you complete each engraving step, remove the resultant from the laser engraving machine.

2. Paint Veneer

During the method one must use the cast acrylic. The cast-acrylic is painted primarily on one part prior to the engraving.

After engraving the cast acrylic creates the best result in the painted part.

The acrylic engraving method is put in steps below

- Paint a part in the cast acrylic

- Cast acrylics get a coat before you engrave them

- Such a method isn’t unlike the rest

- Here the cast acrylic gets a coat on a side

- Create the design that you like to engrave

- Place the formed picture in the laser engraver

- Switch the machine on

- Check if you got the result after you engrave the product

- Take away the engraved picture

- After you remove the engraved product the machine’s power is switched off

3. Rotary

When you want the image to rotate for slicing into the acrylic substance use this method.

Special cutters help in completing in-depth cuts that are clear in the acrylic substance.

Set the right geometry in the cutter to create the best cuts.

Fix the correct clearance angle in the rotary engraving acrylic since it creates chip clearance and clear cutting edges.

Use sixty degrees set points for the cutter and 0.005 or 0.007 height.

Groove the letter sets to create a v form which improves the attractiveness in the acrylic.

Use the ninety degree cutter angle as well as tip size.

Moreover, use a bigger cutter angle to get in-depth cuts. Alter the rotary engraving process to get fine products by the tips below.

- Speed up the spindles and lower rate of feed

- Use sharper cutter

- Utilize tapered cutter for getting a beveled edge

4. Laser Method

Since it uses the laser beams the end result is super-beautiful.

The material is vaporised by the laser that is why we get such sleek products.

Place the light wavelength to ten point six microns while placing the setting power to ten watts.

Here you get the engraving result on double sides.

It is profitable when the behind part is also engraved.

This happens since the product now has the ability to portray better dimensions.

The sleek perfection is highly noticeable. Put the engraving text or picture in the reverse form in order to get the correct reading pattern in the result.

Utilize the laser engrave program to get such a result. Also use the mirror option.

Get the right layout picture before you engrave the acrylic.

Hence, you place it in the right location. Use five percent power, hundred percent speed and thirty watts.

Benefits of the Engraving Process with Acrylic Materials

1. Enhance the Appearance – It enhances the look of the acrylic substance alongside creating remarkable acrylic sheet sets.

2. The Prints are Clear to Read – The look of any dull print is transformed to something attractive through the acrylic substance. That is created thanks to the computer program that sharpens the design and image.

3. The Durability of the Engraved Acrylic Products – These special acrylic substances see to it that it creates a stronger product which lasts for many years with no damage. When there are no friction key holders, logos and portrait photographs last for a long time.

4. Suits any Product – This method creates different types in products. Hence, this method can be used for many businesses and sectors. Nowadays, one can create a signboard, photograph, name tag, menu, or even a jewellery item.

5. Create Precise or Same Writing – Use the latest tools in science to create perfect letters and writings. Machines create better consistent results that are crystal clear.

6. Maximum Safety – Since all lasers are handled with utmost safety procedures this process ensures total safety before starting the engraving.

7. High Efficiency – Use any acrylic sheet of any depth or height. Thus, you achieve high efficiency that creates several positive outcomes.

8. This Method is Fast – The process helps to create several designs from acrylic substances.

Points to Consider for the Acrylic Engraving Process:

Temperature – To get the right quality in the resulting product you must choose the temperature. Use the correct temperature while setting the laser to avoid any burning.

Correct material – When you need a particular effect use the correct acrylic material. For instance, while one needs the frosting white result one can utilize the cast acrylics.

Your safety – Any use of lasers calls for extra safety measures. Use all safety gear always while operating the laser.

Common Problems in Acrylic Engraving

- The mirrored reverse side step takes more time than other methods

- The paint veneer method also takes a lot of time

- The rotary technique needs to follow tough rules in the setting for creating the best products.

Other Issues Related to Method and Designing

1. Burning After Engraving

Use the right information about the acrylic material.

Use the correct condition. Use the best temperatures.

Pick the speed according to the process.

Some need one hundred and the other need only five or ten percent speed.

Start testing with a sample acrylic substance prior to beginning to engrave. Such a step shall alter the condition types to gain the correct result.

Use the direct-to-acrylic to engrave at times

2. Tips to Stop Burns

Lessen the dot per inch to engrave anything. Here the laser vaporizes in the acrylic’s upper layer eventually avoiding any burning.

Use the right acrylic substance to create the frosty white while you engrave

Utilize the cast acrylic that transforms into the frosty result after you engrave

3. Tips to Avoid Inconsistent Results

Try the lesser resolution like three hundred dots at each inch. Change black graphic to eighty percent.

Choose the thin wet sheet of newspaper aka a paper towel for the engraving place.

Such a step allows heat to dissipate but do check if the paper has no wrinkle.

Polish the place using no-scratch scour pads to remove acrylic wastes.

4. Engraving is Slow

Check if you clean the machine always. Check if you have removed dirt or other wastes. Next, see if the lense or mirror is sparkling clean and not dirty.

5. Laser Engraver Fails to Give out Light while Acrylic Engraving

Click on the control panel option to find the status saying it is switched on. Find if any lens is damaged.

6. Various Depths while Engraving

Check whether water circulation is flowing smoothly.

Readjust the focal lengths. Check if the path of the light path is at usual level or alter it correctly.

Re-alter the crossbeam to check the parallel value.

Applications of Acrylic Engraving

This engraving method creates ‘eight’ great new creations for any business.

1. Key Holders – According to the various preferences of the customer you can create personalized key holders with acrylic substances.

2. Business Card Cases – You can build the seductive and stylish business card case for any company or business.

3. Cost List Holder – Create a pretty cost list for huge company areas like the malls.

4. Logos – Engrave the logo for any company, business alongside any school with the acrylic substance. You get incredible results.

5. Menus – Engrave the menu for any hotel with acrylic substances for enticing customers.

6. Engrave Jewelry – Several pieces of marvelous looking jewelry are created by this method.

7. Acrylic Name Plate on the Official Desk – Engrave names inside official areas of any business. Such a tag with the name helps you to recognize officials and staff in a company.

8. Engrave Photographs in Acrylic – Engrave any portrait in the best acrylic to create remarkable results.

Verdict

Now, you know how to use the right method in acrylic engraving. Use the rare tips and methods mentioned above to create beautiful and long lasting acrylic products for your company. Time to etch outstanding images on phenomenal acrylics!