Pleasant Plastic provides a variety of acrylic polishing services throughout the nation. With the appropriate polishing techniques, acrylic components can have optically transparent finishes. In this extremely diligent process, we employ skilled craftsmen with many years of professional experience. Depending on your demands and the type of acrylic you’re dealing with, we offer a variety of acrylic polishing procedures.

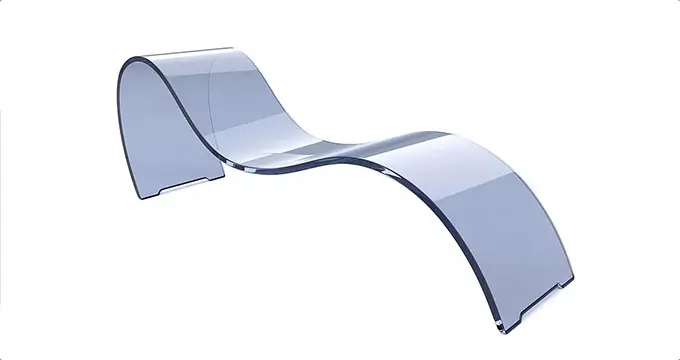

We can also machine and polish your acrylic to provide the greatest possible finish. There are times we receive components to polish that have scratches, thumbprints, and other defects that polishing alone cannot eliminate. We take care of your acrylic while polishing it with acrylic polishing machines, and we have the experience of polishing acrylic required to accomplish the task without defects. The outcome would be a clear acrylic product free of marks and scratches.

Our major polishing services include manual and mop polishing, and a specialized Vapor Polishing technique when extraordinarily high levels of optical clarity are required. Acrylic may be polished to a glass-like sheen with stunning optical clarity and optical characteristics similar to glass using vapor polishing. Colored Acrylics are also polished to give a high aesthetic value.

Mop polishing improves surface smoothness and attractiveness. Vapor polishing is a specialized way of polishing plastics to improve optical clarity and/or minimize surface roughness. A component is often subjected to a chemical vapor, which causes the surface to stream and improves the smooth texture.

To manufacture a product with minimal witness marks in significant spots, start with a careful selection of machine tools, thermal treatment, diamond milling, machining procedures, and preparatory operations.