How Does Laser Engraving Impact the Quality of Acrylic Products?

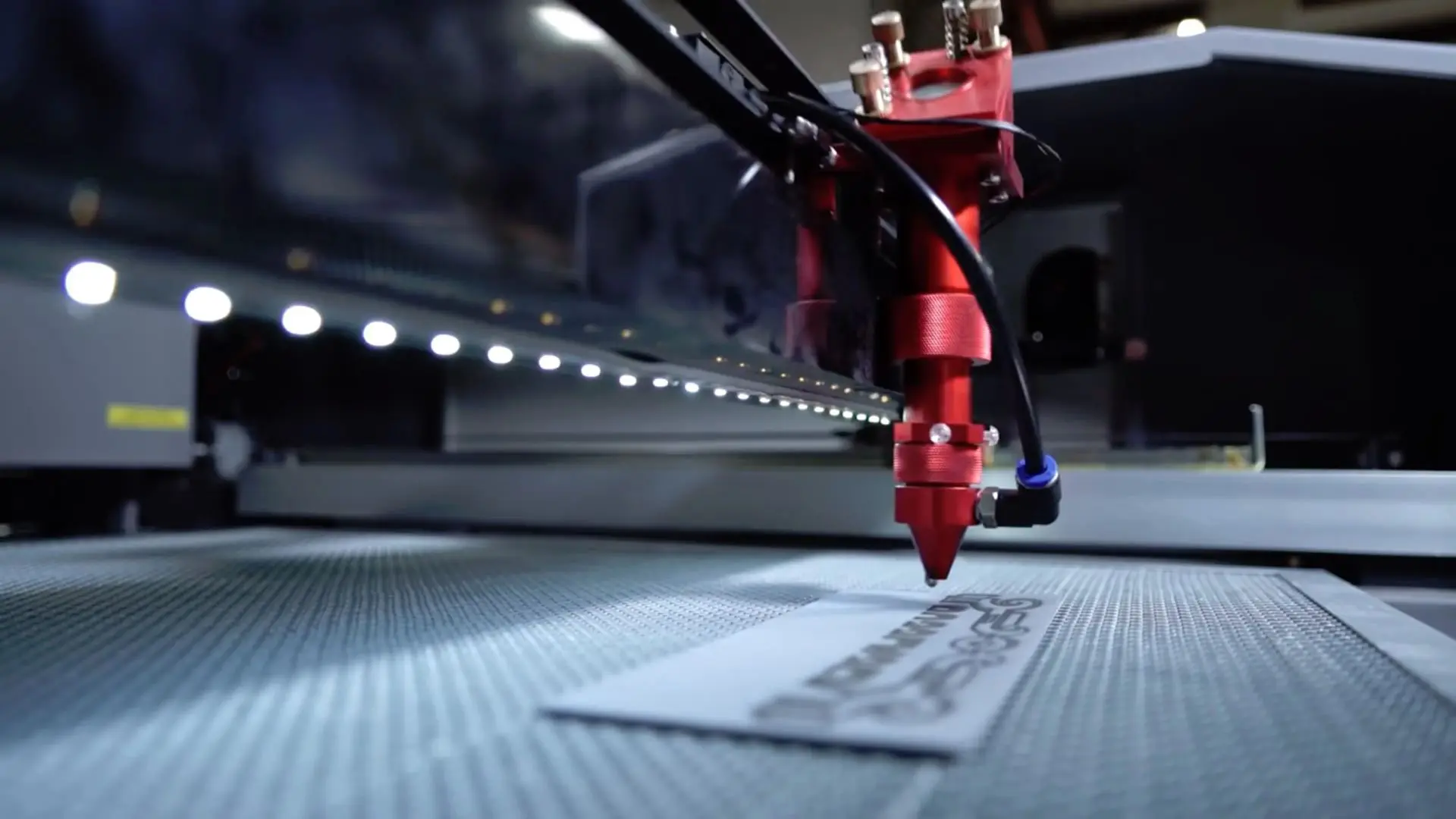

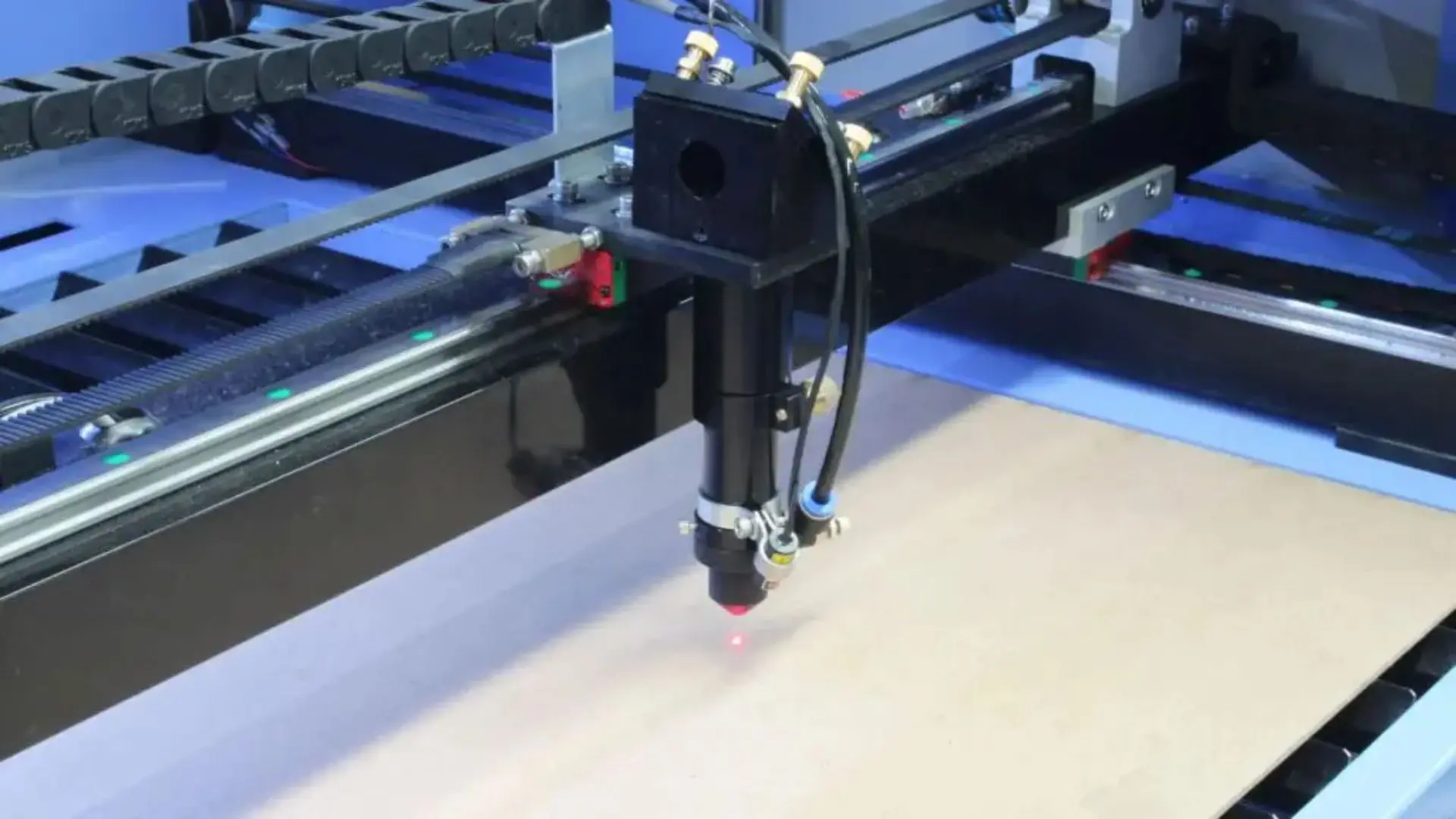

Laser Engraving has grown to become one of the methods that give acrylic products a touch of beauty and functionality. It uses a focused beam of light to trace designs, logos, or text onto the acrylic surface for quality and high-resolution engravings. This blog, therefore, seeks to discuss how engraving enhances the product quality of acrylic by identifying the benefits that make it most preferred in different industries.

Precision and Detail in Engraving

One of the most significant impacts this engraving on acrylic products has been in terms of high precision. One can use a laser for creating intricate designs, fine details that earlier seemed very hard to attain in this industry. This makes every design, be it a complex logo or fine text, crisp and clear to enhance the quality of the product. Such engraving accuracy is handy during the production of products that require customization and where tiny details make a difference.

Consistency in Product Quality

This implies that the same output is achievable over a variety of acrylic products. This is a very important aspect if one wants to maintain brand identity where the products produced are concerned. Whether it is the engraving of one promotional batch or various special ordered pieces, the laser works so that all the products produced are of the same quality. This consistency enhances the products aesthetic appeal and provides them a higher perceived value, thus attracting more customers.

Durability of Engraved Designs

The designs that come out after engraving on acrylic products are way much durable than those that are printed or labelled. The laser creates very permanent marks into the acrylic surface, and such marks are never vulnerable to fading, surface scratching, or peeling of any kind. Their hardiness ensures the design of the engraving will be constant, with the same quality and newness even in prolonged use.

Enhanced Aesthetic Appeal

It imparts a lot of aesthetic enhancement to acrylic products. The engraved designs are clean and professional, giving the products an elevated look. It ensures that any simple piece of acrylic, whether used for awards, signage, or decoration items, is sure to burst forth into being a piece of beauty. The facility of customized designs opens up a gateway to further creativity and personalization, which then qualifies as a selling point for many products.

Flexibility in Design and Application

This engraving can be used on all types of acrylic products, starting from the simplest acrylic keychain to large panels, with perfect quality. However complicated the design may seem, the laser manages to produce simple, but very detailed, designs. This flexibility opens up different types of projects that various businesses can offer to their customers, maintaining the diversity of their needs and tastes.

In Conclusion

Improvement in the quality of acrylic products is associated with this engraving, since it is related to precision, uniformity, durability, and beauty. If you wish to improve the quality of your acrylic products through laser engraving, then Pleasant Plastic offers world-class services that ensure exceptional results all the time.