How Laser Engraving Differs from Laser Cutting

When you need precise design work on materials such as acrylic, wood, metal, or Plastic — for branding, signage, or bespoke products — you’ll often hear two terms: laser engraving and laser cutting. Although both use focused laser beams and computer-controlled paths, the two processes differ significantly in purpose, effect, and final output. If you search for Laser engraving Dubai, you’ll find that many top-tier providers — especially Pleasant Plastic — specialize in either or both services. In this blog, we dive into how laser engraving differs from laser cutting, and when to choose one over the other.

What is Laser Cutting?

The laser cutting technique involves using a high-powered laser beam to slice all the way through a sheet or block of material. The focused laser follows a pre-programmed path, melting, burning, or vaporizing the material to separate it cleanly.

Key features of laser cutting:

- Full material penetration: The beam completely cuts through the thickness of the sheet.

- Clean, polished edges: The cut edges are generally smooth and, for the most part, require little or no additional finishing.

- High precision & repeatability: A computer-controlled laser (sometimes CNC-guided) is able to provide accurate, consistent cuts, ideal for complex shapes, signage, furniture components, or display units.

- Material versatility: laser cutting works on acrylic, Plastic, wood, thin metals, fabric, paper, and more.

Whenever a business requires cutting of acrylic for signage, display stands, furniture parts, or any other modular part that needs to be separated from a larger sheet of acrylic, laser cutting becomes the preferred method. That is a service regularly offered by Pleasant Plastic.

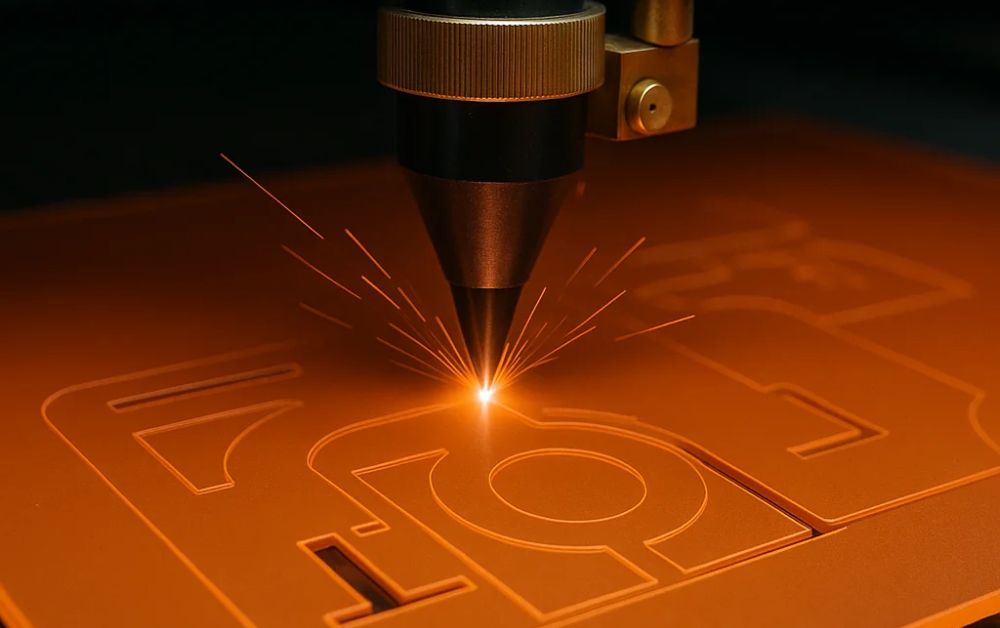

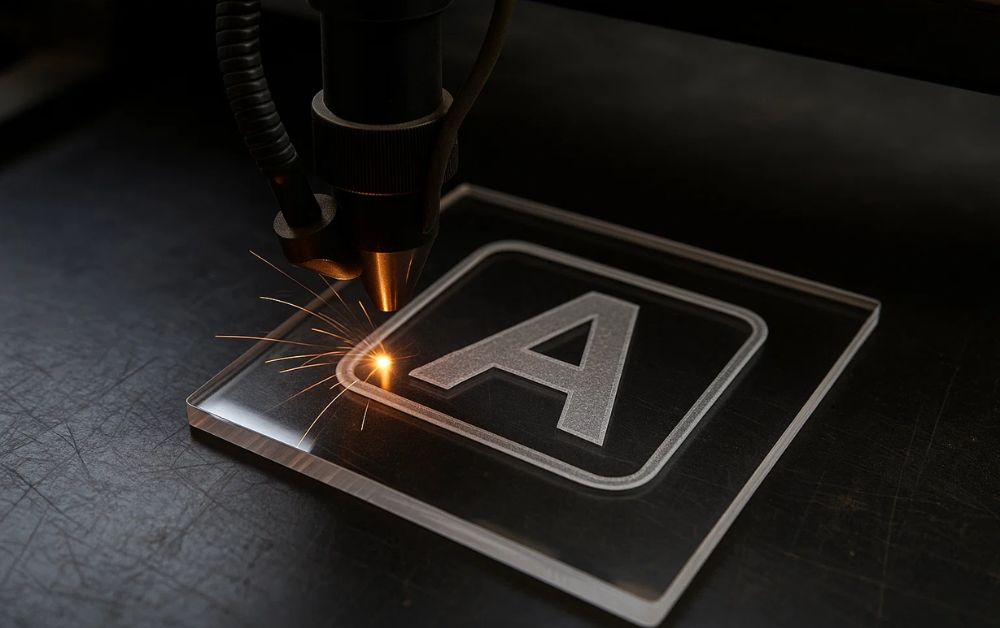

What is Laser Engraving?

Laser engraving, on the other hand, is utilized to etch designs, patterns, or text onto the surface of a material without cutting all the way through. The laser ablates or vaporizes a thin top layer, thus leaving a visible mark.

Essential characteristics of laser engraving:

- Change at a superficial level: the top is taken off only, with no separation or cut-through.

- Contrast – Visual: Engraving on materials such as clear and colored acrylic creates a frosted or matte finish that serves as a nice contrast to the surrounding surface.

- Non-contact process: Without any touching of the blade or tool, there is hardly any risk of scratches or mechanical damage.

- Ideal for text, logos, and decoration: Engraving is best when you want to add branding, labels, serial numbers, decorative patterns, or personalized artwork — without altering the shape or structural integrity of the material.

Pleasant Plastic’s acrylic engraving is listed as one of the primary services offered, including custom signage, decorative panels, and branding elements.

| Feature | Laser Cutting | Laser Engraving |

| Purpose | Tell apart parts; make shapes, cut-outs, components | Add surface designs, logos, text, and decoration. |

| Material Interaction | Cuts all the way through the thickness. | Removes only the surface layer |

| Results Appearance | smooth, polished edges; new shape or part | frosted/mat finish; original form still recognizable |

| Best For | Signage letters, panels, furniture parts, stencils, structural components | Logos, labelling, awards, plaques, decorative elements |

| Material Thickness Suitability | Thin to moderately thick sheets, depending on laser power. | Thin to thick surfaces — depth controlled by laser settings |

| Post-processing Needs | often minimal edges are smooth. | Minimal — since only the surface is etched. |

This summary emphasizes what the basic, differentiating characteristic of the two procedures is: cutting is structural, engraving is decorative or informative.

When to Use Which — And Why

Choose Laser Cutting When:

- You have to separate parts, for example, cut letters, shapes, or panels out of acrylic sheets.

- You are manufacturing items that need structural strength, such as acrylic display cases, parts of furniture, or covers.

- Clean edges and an exact shape are crucial.

Choose Laser Engraving When:

- You want to add text, logos, or decorative motifs on the surface without changing the overall shape.

- You are personalizing awards, signage, labels, or personalized items.

- You want contrast and delicate detailing on acrylic, wood, metal, or other materials.

Many professional shops, such as Pleasant Plastic, offer both services under one roof, thereby acting as versatile providers of various fabrication needs.

Why the Distinction Matters

Understanding the difference between laser engraving and laser cutting is not merely academic: this is how you select the proper process for your requirements, save time and cost, and make sure that your final product looks and acts exactly as you have in mind.

- If you ask for engraving when you actually need cutting, you’ll be left with a flat, un-separated sheet.

- If you request cutting when you need only decoration, you may be unnecessarily destroying the material.

- Correct selection also ensures the best utilization of materials, minimal waste, and appropriate finish and durability.

Whether your project requires surface engraving or full-thickness cutting, this can mean a great deal for businesses or individuals in search of top-quality acrylic work in Dubai.

Why Choose Pleasant Plastic

When you search for Laser engraving Dubai, Pleasant Plastic stands out. As a market-leading acrylic fabrication company in Dubai, Pleasant Plastic offers a full suite of services-from laser cutting and engraving to polishing, bending, molding, and custom finishing.

Their expertise ensures:

- High-precision laser cutting and engraving using modern laser and CNC technologies.

- Clean, polished edges when cutting acrylic sheets for signage, furniture, display units, or protective covers.

- Quality surface engraving: crisp, clear text or logo marking on acrylic surfaces with a frosted or matte finish.

- Flexibility in customization: from individual design requirements to corporate branding, décor, and functional product parts.

Conclusion

While the end goals, techniques, and outputs of laser engraving and laser cutting differ drastically, both rely on concentrated, computer-guided laser beams. Engraving is for surface decoration or marking, while cutting is for structural shaping and separation. For anyone in Dubai searching for Laser engraving Dubai, especially when looking for high‑quality acrylic work, Pleasant Plastic offers reliable, dual‑capability services to meet both cutting and engraving needs. From sharp-edged acrylic panels to intricately engraved logos and designs, understanding the difference will ensure that you get precisely what you want.